Ultimate Elaboration: Ceramic Sculpture

Introduction by Keiko Fukai

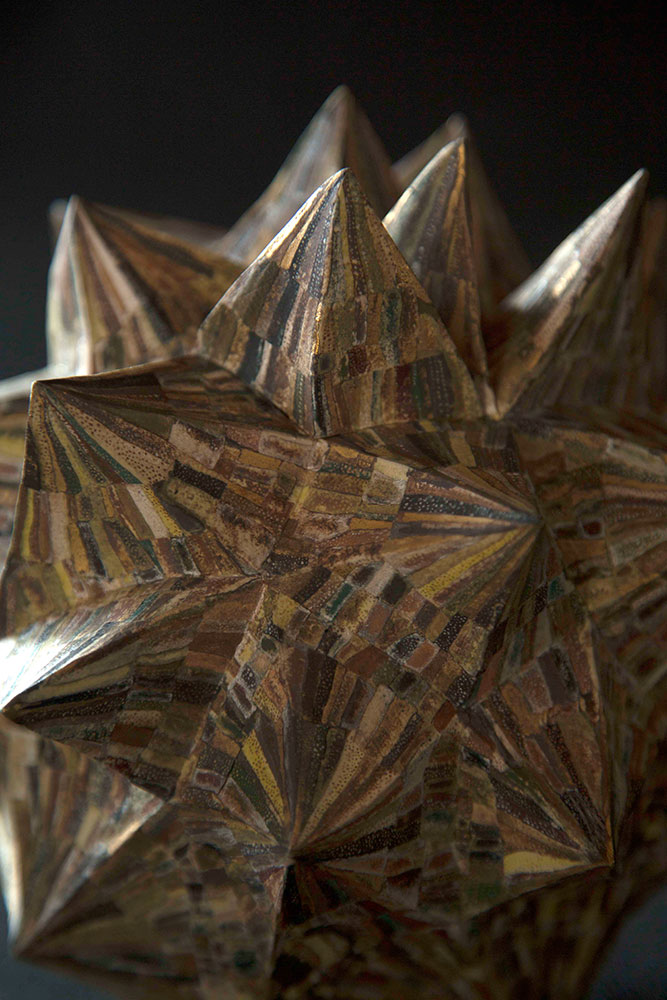

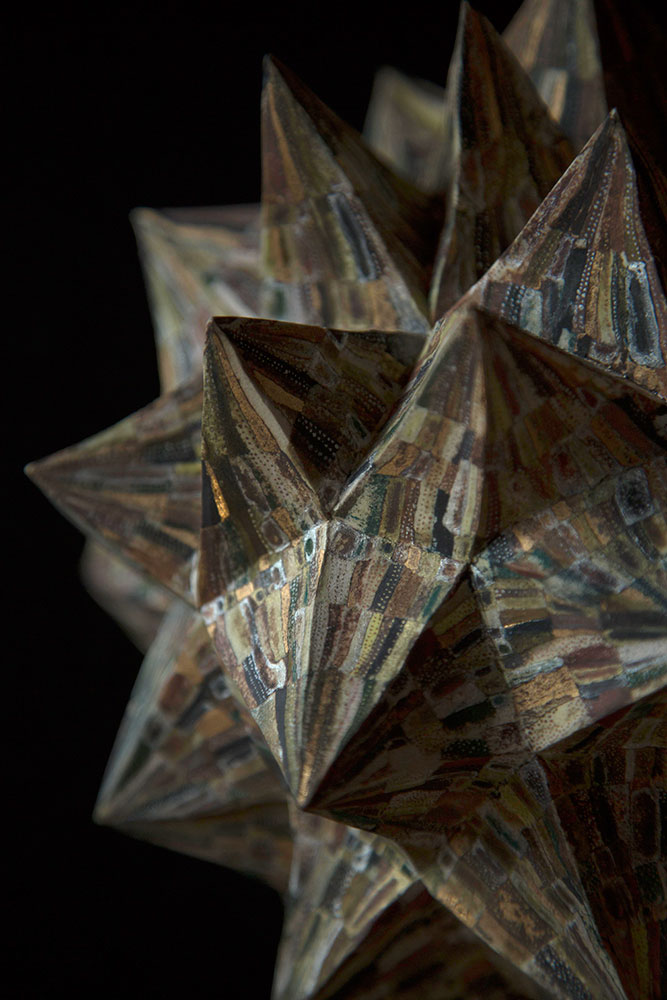

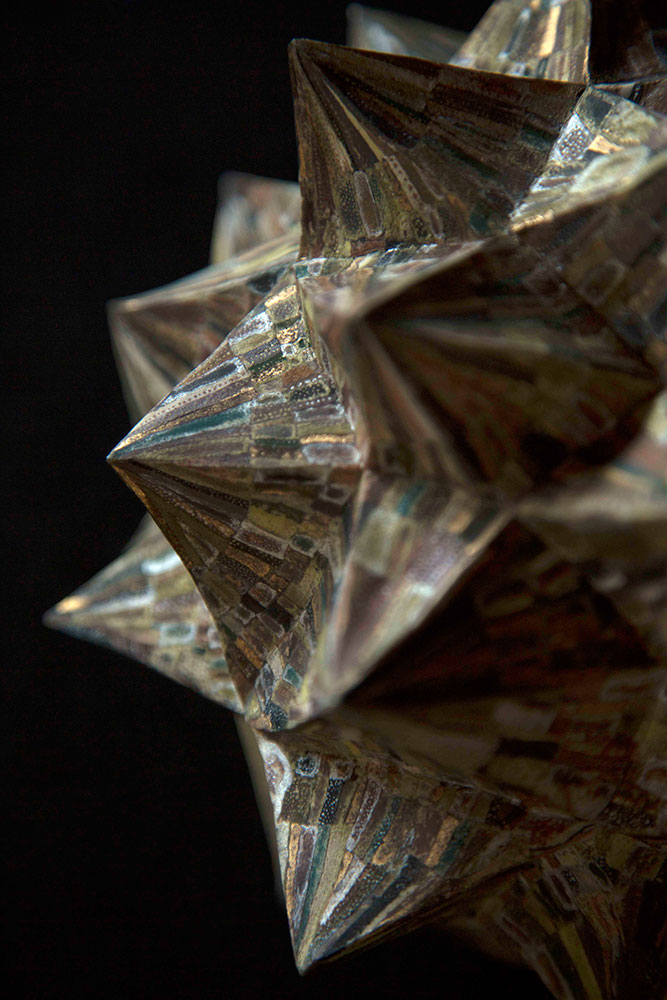

INAZAKI Eriko, who resides in Takamatsu City has been creating amazingly detailed ceramic sculptures since 1993. Her sculptures are composed of thousands of porcelain micro parts, all made by hand. How small are these parts? The little balls of porcelain are the size of poppy seeds, and the thin rods are like the small bones of a sardine. It is not surprising, therefore, that it takes several months to complete one sculpture, even though she can make one thousand of these small components in a single day.

Most of Inazaki’s sculptures are reminiscent of flora and fauna, and even coral, but recently her style has moved toward a very different conceptual direction. She says that we have long understood that many machines familiar to our everyday lives can have artificial intelligence. To Inazaki the millions of tiny parts of these machines look like cells and, to her, the machines often seem like living creatures. She wanted to create something that seemed to be given the breath of life, like human beings.

For this online exhibition, we have created a brief film that illustrates her complicated processes which will hopefully clarify the manner in which she creates her sculptures.

Most of my works share a feature of the accumulation of tiny parts. These tiny particles, seemingly gathered on the surface over time, create beautiful rhythmic waves.

In the beginning of the process, I create roughly shaped bodies of clay. Before applying the parts on the surface of the body, I usually make a thumb size sample of the piece, using the tiny parts. This trial piece is not a maquette for the completed piece, but it gives me the idea the whole composition as well as the effect of light and shadow. After I get a vague idea from this sample, the process of attachment begins without any specific ideas. While I am creating and adding the tiny parts to the surface, I get some inspiration, and then a theme of the piece emerges.

Most of these tiny parts are made by porcelain and are shaped in different designs and sizes. For example, to make a one millimeter thickness porcelain rod, I roll the clay into the size of angel hair spaghetti and cut it into smaller sizes; or to make a 3mm window frame shape, I roll out the clay like paper thin pie dough and cut it with a knife. These tiny parts are attached to the surface with water, so it is important to keep the piece appropriately moist so it doesn’t become brittle. For that reason, I have to make the parts one by one before attaching them on the surface. This procedure slows down the execution which is already an onerous and complicated process. One more important thing is keeping the entire piece moist until all the surface application is finished. I make my pieces in a framed vinyl-covered box which stands on the desk, and a humidifier always produces steam near this box. Until the end of the day, the mist is sprayed, and the front of the box is sealed with a vinyl sheet to retain the humidity overnight. It takes about three to six months to finish applying all the small parts, and it is ideal if the drying time equals the execution time. In considering this complicated process, I sometime feel that I am growing the piece—a more appropriate expression than creating or decorating the piece.

Depending on the piece, they are fired two to four times in a gas kiln. The glazing involves glass, powdered feldspar, or silver mica according to what each piece requires.

As a child I was always fascinated to find star-sand or unusual patterned tiny mineral crystals, and I cherished these fragments of nature very much. All of them belong to the earth and were natural accompaniments to clay and now they create small pieces of my destiny. Whether the objects are small or large, the fact that everything is composed of micro particles appeals to me a lot. The reason I prefer to create from the smallest possible units may come from this preference. I create my sculptures as the insects make their niduses, but I never have the feeling that I am decorating the piece.

Finally, I have to reveal a bit of magic in my pieces. I take full advantage of the way clay shrinks as much as 15% to 20% during the firing process. I make the components as small as possible but they become much smaller in the kiln, and the some parts became crystalized, expressing a different beauty.

It’s at that moment I feel my sculptures exceed the capability of hand-making, because this shrinkage creates the maximum impact on my pieces. I feel that the firing allows my sculpture to transcend into another sphere. When I look at the fired pieces and feel that my effort has paid off, I feel purified. This kind of satisfaction might be the reason I can continue to make such elaborations with clay.